The OttOmate Guide to NSF Certification - Technically Speaking: Temperature Requirements and Validation

Temperature matters! Learn about your danger zones and how to test them.

The FDA categorizes foodborne-illness risk factors into four problematic areas: poor personal hygiene, contaminated equipment, improper holding temperature and inadequate cooking. Three of these areas apply to equipment. Equipment designed to hold food which supports microbiological growth needs to properly heat, cool and store food.

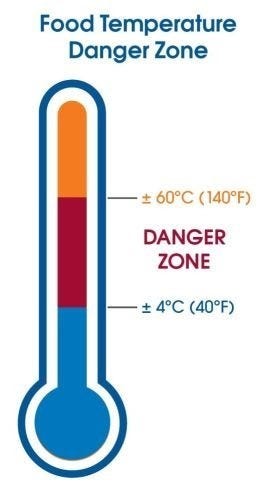

The “Temperature Danger Zone” for Food

Bacteria such as Salmonella and E. Coli are some of the most well-known and widespread bacteria relevant to food contamination. They grow most rapidly in temperatures ranging from 4°-5°C (40°-41°F) and 60°-63°C (140°-145°F), doubling in as little as 20 minutes. These temperature ranges are often called the "danger zones.”

As part of the NSF certification process, machines undergo testing to ensure they are able to (when applicable):

Store food at a safe temperature (either refrigerated or heated).

Cool down or reheat food past this “danger zone” in the shortest time possible.

Testing Requirements

To simulate a normal-use environment, all tests are performed in a calibrated climate chamber capable of maintaining stable ambient temperatures and (sometimes) humidity around the unit. This helps create uniform conditions that are close to “real life.”

Refrigerated equipment is typically tested in ambient conditions of 38°C (100°F) for long-term storage equipment such as refrigerators or freezers, or 30°C (86°F) for short term storage such as drinks dispensers with fresh beverages.

Heated storage equipment such as hot display cases or soup stations are tested in 23°C (73°F) ambient conditions.

Storage Equipment: No-load or Medium Test

Long-term storage equipment (e.g. refrigerators and closed display cases) typically undergo a no-load test where the air temperature inside the storage compartment is monitored at top, in the center and bottom for four hours.

For short-term storage equipment (e.g. beverage dispensers) that only hold a small volume of food for dispensing, testing is performed with the actual intended medium of the device. The temperature is monitored inside the product storage area and in the dispensing spout. The aim is to ensure that even at the last point of dispensing, the food is kept at a safe temperature.

Reheating Equipment and Blast Chillers

Reheating and blast chiller machines are evaluated to verify they can pass food through the “danger zone” in the shortest time possible. They go through a full-load medium test where the maximum allowable time is either two hours (for heating), four hours (for rapid cooldowns) or whatever is claimed in the product manual (going with whichever time is less).

Open Equipment

Further protocols are specified for open refrigerated equipment under NSF/ANSI 7, such as display coolers, sandwich preparation tables, salad bars, etc. Similar open heated equipment, such as steam tables, fall under the protocols outlined in NSF/ANSI 4.

Thermometer Accuracy

In addition to the temperature studies, performance testing also verifies the units have a permanently installed thermometer for the end user or public health inspector to check the food/air temperature at all times.

This thermometer also undergoes an accuracy test, ensuring it displays the actual temperature present in the food or food storage area. An accuracy margin of ±1°C/2°F is typically used in the testing criteria.

This completes the various areas of food safety in food equipment. Next week, we’ll wrap things up with a final article on food equipment certification, bringing all these steps together.

This article is part of the OttOmate Guide to NSF Certification. Visit ottomate.news each Wednesday for the latest article. For more information, contact NSF at foodequpimentinfo@nsf.org or visit their website to learn more.