The OttOmate Guide to NSF Certification: Technically Speaking: Performance Testing

What are performance tests, and why might you need to do them?

Depending on the product, functionality and standard requirements, performance testing may be required for certification. Performance tests help to protect public health and ensure hygiene by varying aspects, such as microbial reduction via clean-in-place, material adhesion and heavy metal content, and accurate temperature management.

Performance tests may include:

Clean-in-place (e.g. beverage dispensers, ice machines)

Organic coatings (e.g. paint, epoxy, lacquer)

Temperature requirements & validation

Clean-in-Place

NSF/ANSI food equipment standards require equipment to have food zones that are cleanable by hand; however, for some machines this may be impossible to achieve. When manual cleaning isn’t possible, manufacturers rely on clean-in-place (CIP) procedures to clean and sanitize areas of their equipment that aren’t accessible.

A CIP procedure is a method of cleaning and sanitizing equipment surfaces in their assembled form by mechanically circulating or passing a detergent solution, water rinse and sanitizing solution onto or over the surfaces.

Some examples of equipment that CIP procedures would apply to include beverage dispensers, ice machines, soft-serve ice cream dispensers and blenders. The main CIP determinant is the intent of the equipment and if the design prohibits manual cleaning. Each unit is reviewed on a case-by-case basis to determine if a CIP procedure is necessary.

CIP testing verifies that food buildup and bacteria can be removed when the cleaning and instruction requirements are followed by the end user. This ensures the products served to customers remain safer and comply with national food safety standards. Testing is performed in accordance with standard requirements to validate the efficacy of the manufacturer’s recommended CIP procedure in achieving 99.9999% (or a 6-log bacteria kill rate) reduction of illness-causing microorganisms.

Organic Coatings

A coating is a layer that permanently covers the base material of the equipment. An organic coating is a resin-based coating applied to the base material by a spraying or dipping process. Other products, such as stickers, films, inks or water prints are not considered coatings. Surface treatments such as aluminum anodizing are also not considered coatings.

Different testing and material requirements apply to coatings depending on the zone where the coating is applied.

In the food zone, the coating material must meet FDA 21 CFR requirements. In the food zone, splash zone and exposed nonfood zone, the presence of intentionally added heavy metals is not allowed.

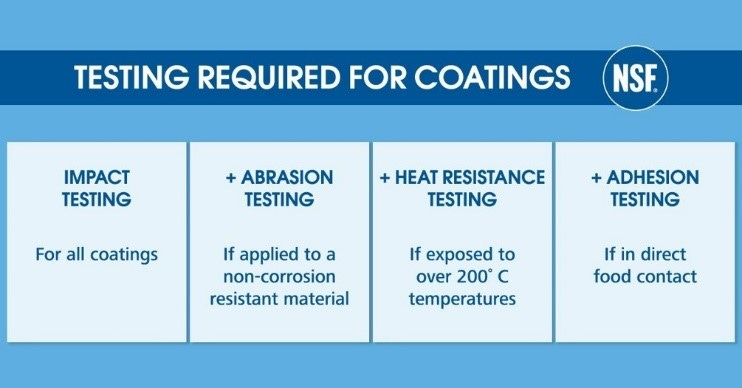

All organic coatings in the food and splash zones undergo performance testing to demonstrate that they adhere to the substrate and do not flake off. Testing depends on the zone:

Impact testing is always required to verify that the coating does not exhibit any cracking when subjected to an impact force, causing physical and chemical contamination in food nearby.

Abrasion testing is required in food zones – it's also required in splash zones if the coating is applied to a non-corrosion-resistant substrate, to prevent a corroded uncleanable surface.

Heat resistance testing is added if the coating will be exposed to a temperature of over 200˚ C.

For coatings in direct food contact, all the above testing is required, as well as an adhesion test

Coatings used in the nonfood zone (underside or interior of the machine) are exempt from testing.

In addition to CIP and coatings, food equipment standards also include temperature requirements and validation. Next week, we’ll share more information on how temperature management is tested. Remember, not all food equipment is created equal, but having your equipment certified by NSF ensures it’s being held to the highest sanitation standards and meets safety requirements.

This article is part of the OttOmate Guide to NSF Certification. Visit ottomate.news each Wednesday for the latest article. For more information, contact NSF at foodequpimentinfo@nsf.org or visit their website to learn more.